Project Overview

This complex automotive dashboard mold project showcases TurkeyMolding's expertise in precision plastic injection molding for the automotive industry. Developed for a leading automotive manufacturer, this project required intricate engineering solutions to meet stringent quality standards and tight tolerances.

The dashboard component demanded advanced surface finishing, complex geometries, and multiple insert molding techniques. Our team utilized state-of-the-art CAD/CAM technologies and 25+ years of mold-making expertise to deliver a production-ready solution that exceeded client expectations.

This project demonstrates our capability to handle sophisticated automotive interior components while maintaining the precision and durability required for high-volume production environments.

Technical Specifications

- Material: ABS + PC Blend

- Mold Type: Multi-cavity injection mold

- Tolerance: ±0.05mm

- Cycle Time: 45 seconds

- Surface Finish: Class A automotive grade

- Production Volume: 100,000+ units/year

- Mold Life: 1,000,000+ shots

- Project Duration: 12 weeks

Manufacturing Process

CAD/CAM Design & Engineering

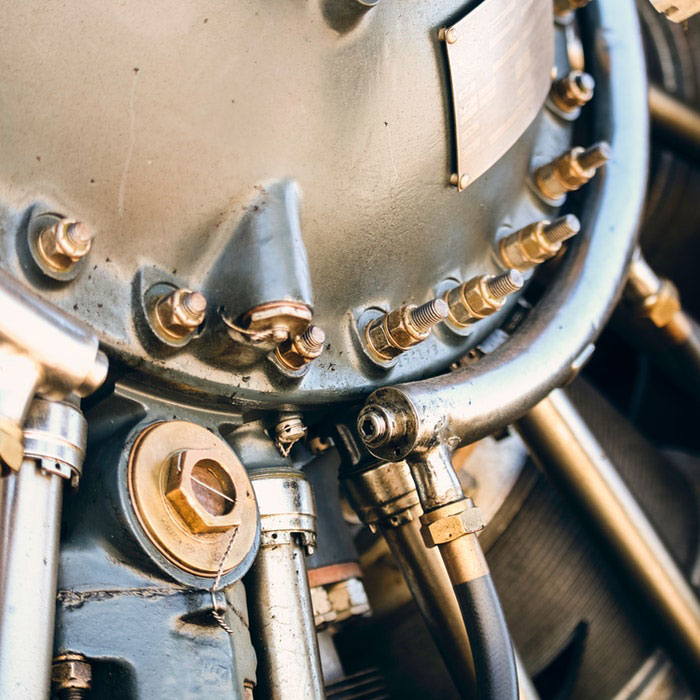

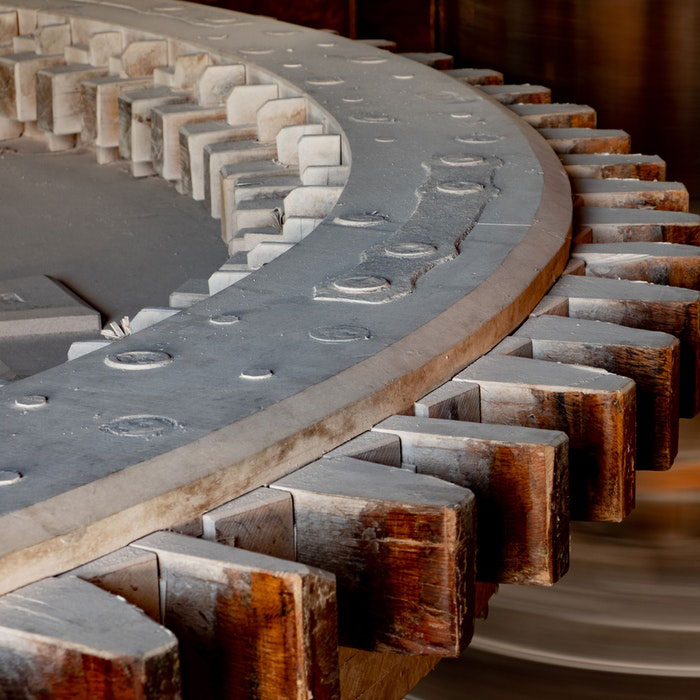

Precision CNC Machining

Quality Control & Testing

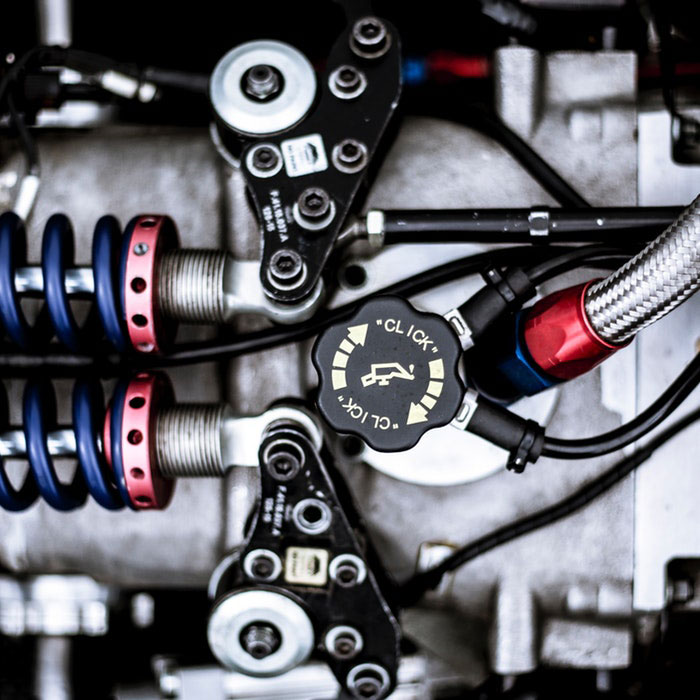

Engineering Challenge & Solution

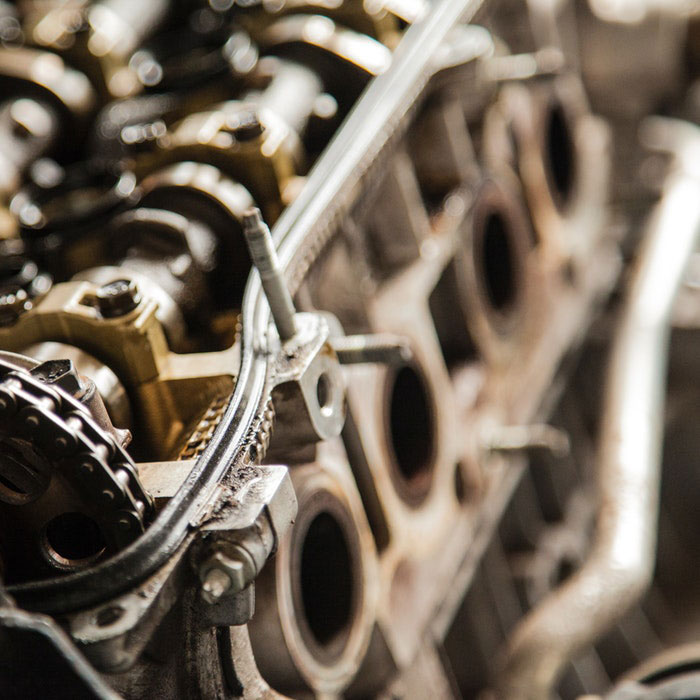

Challenge: The dashboard design required complex undercuts, varying wall thicknesses, and integration of multiple electronic component housings while maintaining automotive-grade surface quality.

Solution: Our engineering team developed a sophisticated multi-slide mold system with advanced cooling channels and implemented a staged ejection system. We utilized advanced mold flow analysis to optimize gate locations and ensure uniform material flow throughout the complex geometry.